Design & Development

Product Design

SST has a wide range of expertise in areas from designing and developing products based on advanced metallic materials, through to precision machining, additive manufacturing, tube forming, welding technique development and quality systems and procedures. SST also has the in-depth engineering competence to run the technical aspects of any project with its highly skilled design, project and quality engineering teams. SST can take a product from concept through to volume production employing innovative solutions to a range of engineering challenges. SST has multiple CAD systems to meet our customers’ requirements alongside in-house analysis and FEA capability that can be validated in our mechanical test lab to demonstrate the product performance and calibrate our design methodologies.

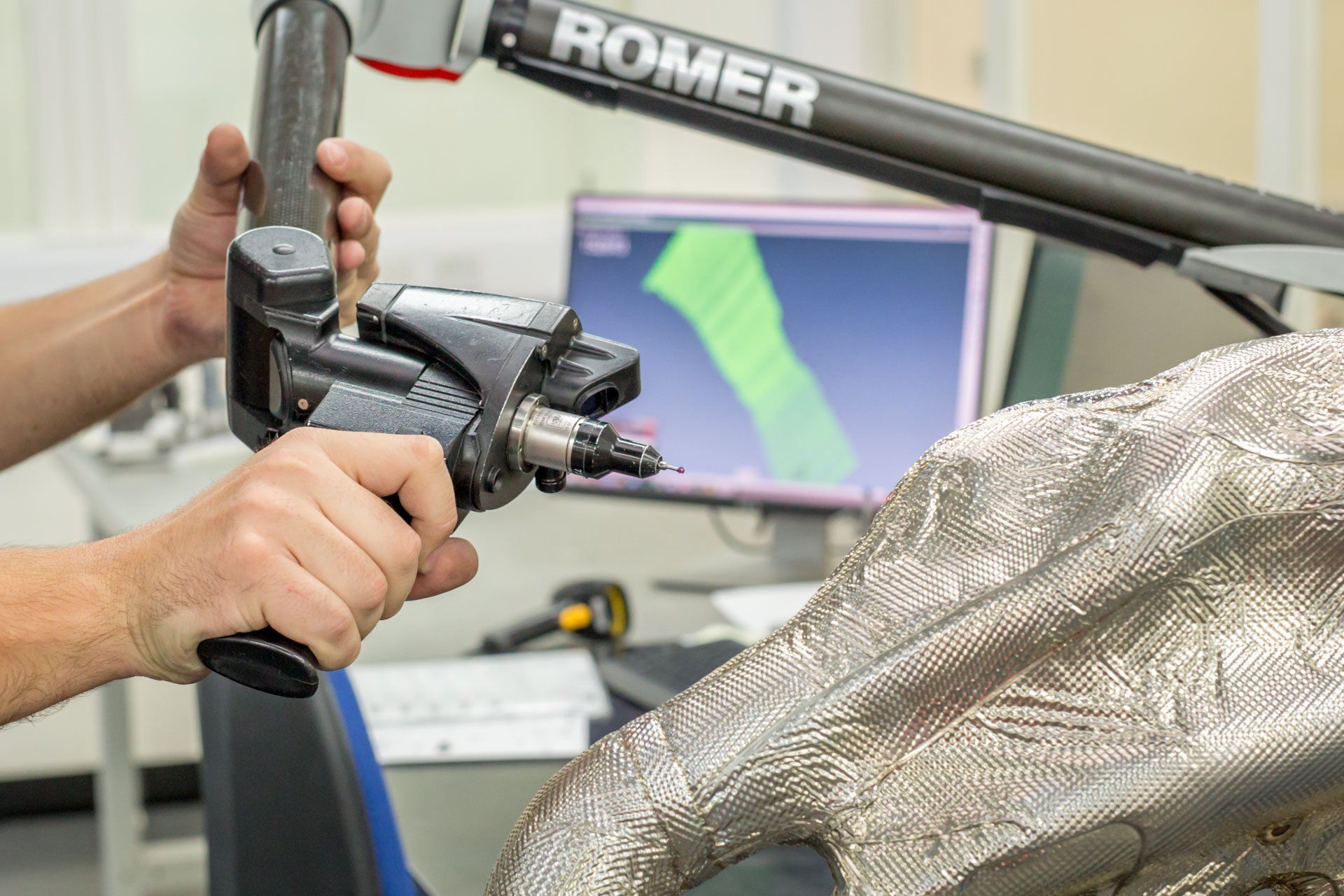

Reverse Engineering

SST Technology has advanced 3D laser scanning equipment which is operated by our trained engineers.

Using this laser scanning capability SST Technology can take an existing system or part and accurately reverse engineer the component, quickly converting it into a CAD model which can then be manufactured again, or be amended to add additional design features or improvements to a particular assembly, component or structure.

The Laser scanning capability can also be used to capture system level data and geometry for where a new part needs to fit into an assembly. This allows us to develop components for customers where a design or data does not currently exist.

This service is utilized extensively in-house, but is also available to our customers should a specific inspection requirement be required.

Analysis & Validation

Non Destructive Testing (NDT) and Natural Frequency Testing

SST Technology can offer a range of different Non Destructive Testing (NDT) options according to requirements. Common methods utilised across many products are:

- Pressure Testing to ensure an exhaust system is fully sealed, and welds have no cracks or pores

- Dye-penetrant crack testing

- X-ray or more detailed Magnetic Particle Inspection (MPI) testing of machined, cast and Direct Metal Laser Sintered (DMLS) components.

We are experts in manufacture of high grade material specialist fabrications and use Poka Yoke jigging techniques to ensure repeatable and efficient manufacture. If desired we can use NDT techniques to verify all welds are in accordance with the specification and can utilize post process techniques such as heat treatment or shot peening to stress relieve in the welding zone.

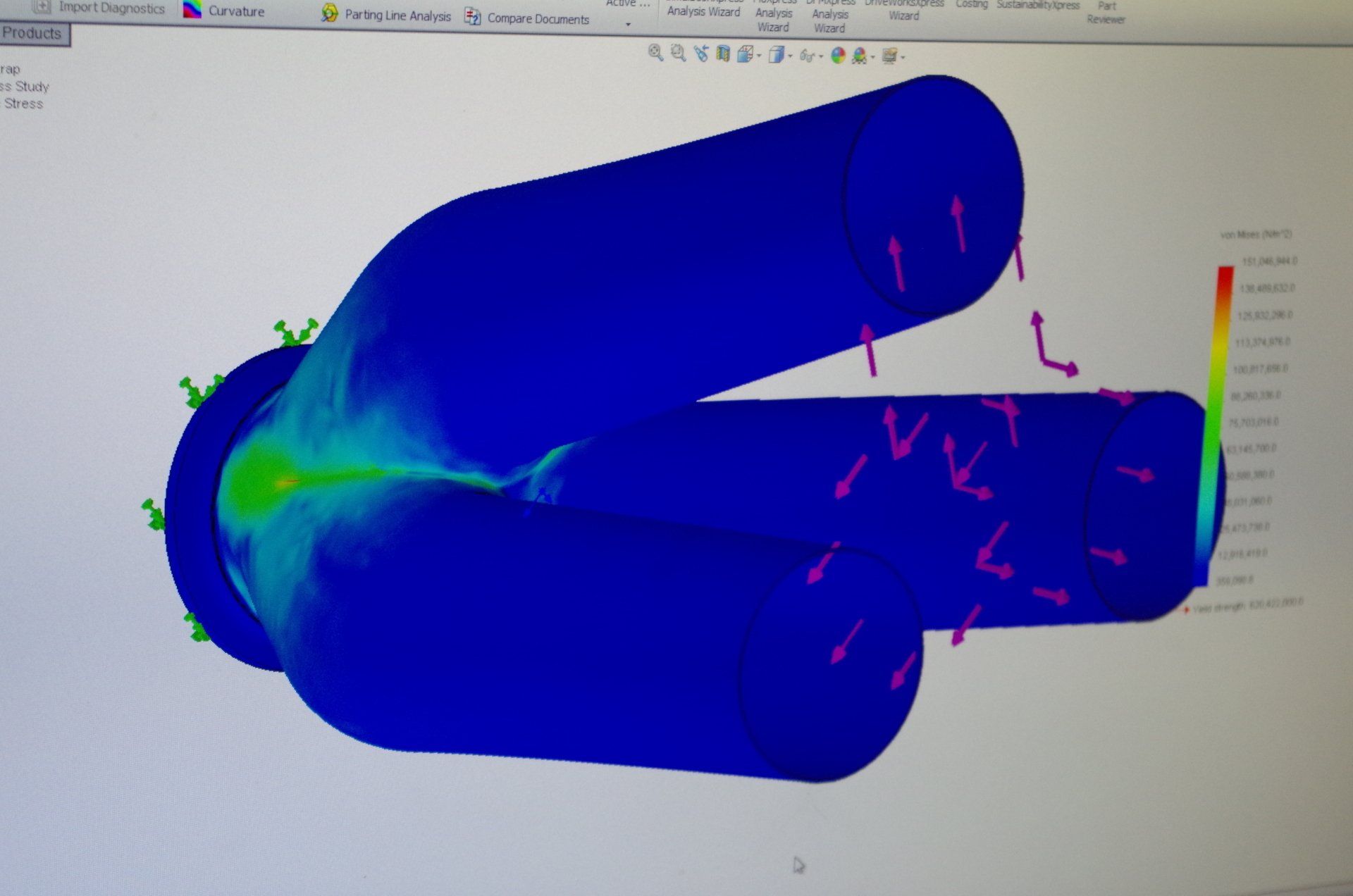

Stress Analysis

SST Technology have a strong engineering core which drives our approach to design and manufacture and can offer a range of design analysis services, from basic FE analysis work to providing thermal analysis of systems in conjunction with the heat shielding that we can offer.

We can also carry out accurate natural frequency analysis and studies of structures, which can be used either as a preventative measure to help avoid vibration issues within an application, or diagnostically to identify potential existing failure mechanisms.

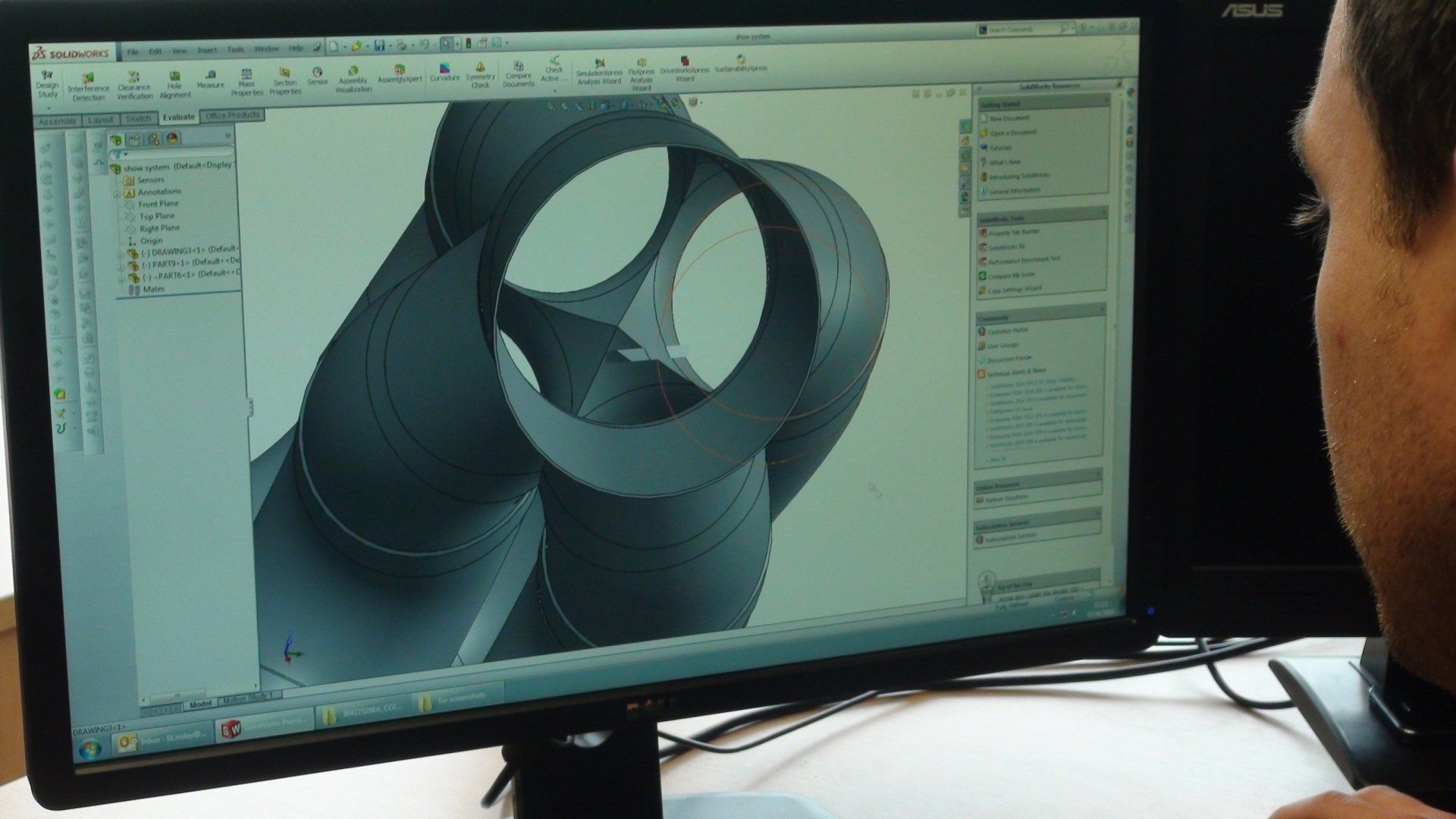

CAD & 3D Modelling

SST Technology can offer a full 3D CAD service, taking a customer’s specification in basic form and developing it into a full 3D CAD model for review and approval. Using our own in-house design code integrated into SolidWorks, we can ensure that the design is correct and fits first time.

Our team of highly skilled engineers work with our customers to deliver the design and manage the development of the components. The data produced is managed using a PDM (Product Data Management) system, ensuring controls of revision history of internal and external documents satisfying requirements of our quality system and guaranteeing the integrity of engineering data at every stage in the business.

Find out more about complementary products and services

SST Technology, together with our partner Lentus Composites provide an array of products and services; blending engineering disciplines and techniques to meet our client’s needs.

-

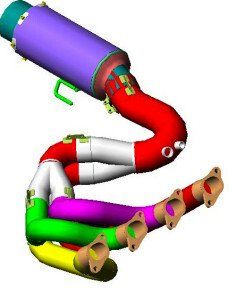

Exhaust Systems

Photo By: John DoeRead More > -

Thermal Management Systems

Photo By: John DoeRead More >

Want more information?

UK Office:

Horizon Technology Park, Stanton Harcourt Rd, Eynsham OX29 4GF

Polar Technology Management Group (Company Reg No. 07861070 Registered office: 67 Hightown Rd, Banbury, Oxfordshire OX16 9BE.)

SST Technology

Website Design by Warpspeed Web